Introduction

Welcome to CAN Bus Basics, a new blog series from Perspic where we demystify CAN Bus systems from a hands-on, engineering perspective.

If you're an engineer, technician, or enthusiast working with embedded systems, vehicles, or industrial equipment, this series is for you. We'll explore how CAN Bus works, how to troubleshoot CAN Bus networks, and how to design your own CAN message structures and networks. Whether you're maintaining agricultural machinery or building your own robotics platform, you'll find something useful here.

Who’s Behind This Series?

Hi, I'm Matthew, a systems engineer at Perspic. I've been working with CAN Bus networks for over a decade (as of 2025) —mostly on tractors, forklifts, and other industrial equipment. Recently, I’ve focused on designing custom CAN Bus solutions with Perspic.

I know firsthand how complex CAN Bus can seem at first. That’s why I’ve put together this series—to make the concepts clear and accessible, while giving you the practical insight needed to apply them.

What Is CAN Bus?

CAN Bus, short for Controller Area Network, is a robust, efficient communication protocol designed for devices to exchange data with one another over a shared network.

Originally developed by Bosch in the 1980s, CAN Bus was created to reduce wiring complexity in automotive systems. But it quickly proved valuable in many other industries.

Why CAN Was Needed

At the time, basic serial protocols like UART were used for module communication, but they couldn't handle the demands of inter-module communication in harsh environments. CAN Bus was the answer.

To transmit data reliably over longer distances (at least by microcontroller standards), engineers needed a protocol that could:

- Provide data transmission between multiple devices on a shared bus, with built-in prioritization.

- Resist electrical noise and interference common in vehicles and industrial settings.

CAN Bus achieves this with differential signaling over twisted-pair wiring, giving it excellent noise immunity and fault tolerance.

Over the years, CAN has evolved. Today, protocols like CAN FD (Flexible Data Rate) offer higher speeds while maintaining backward compatibility with the original CAN standard.

Why Should You Care About CAN Bus?

Because it’s everywhere... and it's super useful.

Modern vehicles—cars, trucks, SUVs, tractors—all use CAN Bus to connect ECUs (Electronic Control Units), sensors, and dashboards. Industrial and agricultural machinery rely on CAN Bus for coordination between control systems. Aerospace, marine, and even medical equipment use CAN for critical system communication. CAN Bus is even in building automation, robotics, and HVAC systems are increasingly adopting CAN-based protocols.

If you work with embedded systems, automotive electronics, or industrial control systems, understanding CAN Bus isn't just useful—it’s essential.

⚙️ How CAN Bus Works: Messages, IDs, and Custom Protocols

One of the key reasons CAN Bus is so useful is its simplicity and flexibility.

At its core, CAN is a low-cost way to transmit data over long distances between multiple devices on a shared network. Instead of running separate wires between every component, CAN lets devices communicate over just two twisted wires—dramatically reducing wiring complexity.

📨 The Structure of a CAN Message

Each CAN message contains:

- A Message ID – This determines both the priority of the message on the bus and what type of data is being sent.

- Up to 8 bytes of data – Enough for many types of sensor readings, commands, or status flags.

Note: With CAN FD (Flexible Data Rate), the data payload can be extended up to 64 bytes, but traditional CAN is limited to 8.

🧩 Message Meaning Is Application-Specific

Importantly, CAN Bus doesn’t define what the messages mean. The protocol only handles how messages are transmitted—not what they represent. That’s up to the system designer.

You decide:

- What each Message ID stands for

- What the 8 bytes of data mean

- How messages are structured and interpreted

This design freedom is incredibly powerful, but it also means that CAN networks are often proprietary.

🔧 Standard Protocols vs. Custom Implementations

To promote compatibility and make development easier in some industries, a few standard CAN protocols have emerged. For example:

CANOpen – Common in industrial automation and robotics

SAE J1939 – Used extensively in heavy-duty vehicles and off-road equipment

However, many manufacturers—especially automotive OEMs—create their own custom CAN protocols. These are often unique to a specific vehicle generation, model line, or control system.

That’s why reverse-engineering CAN messages (e.g., for performance tuning or diagnostics) can be such a deep rabbit hole—there’s no universal message map unless you're working with a standardized protocol.

CAN Bus Architecture and Layout

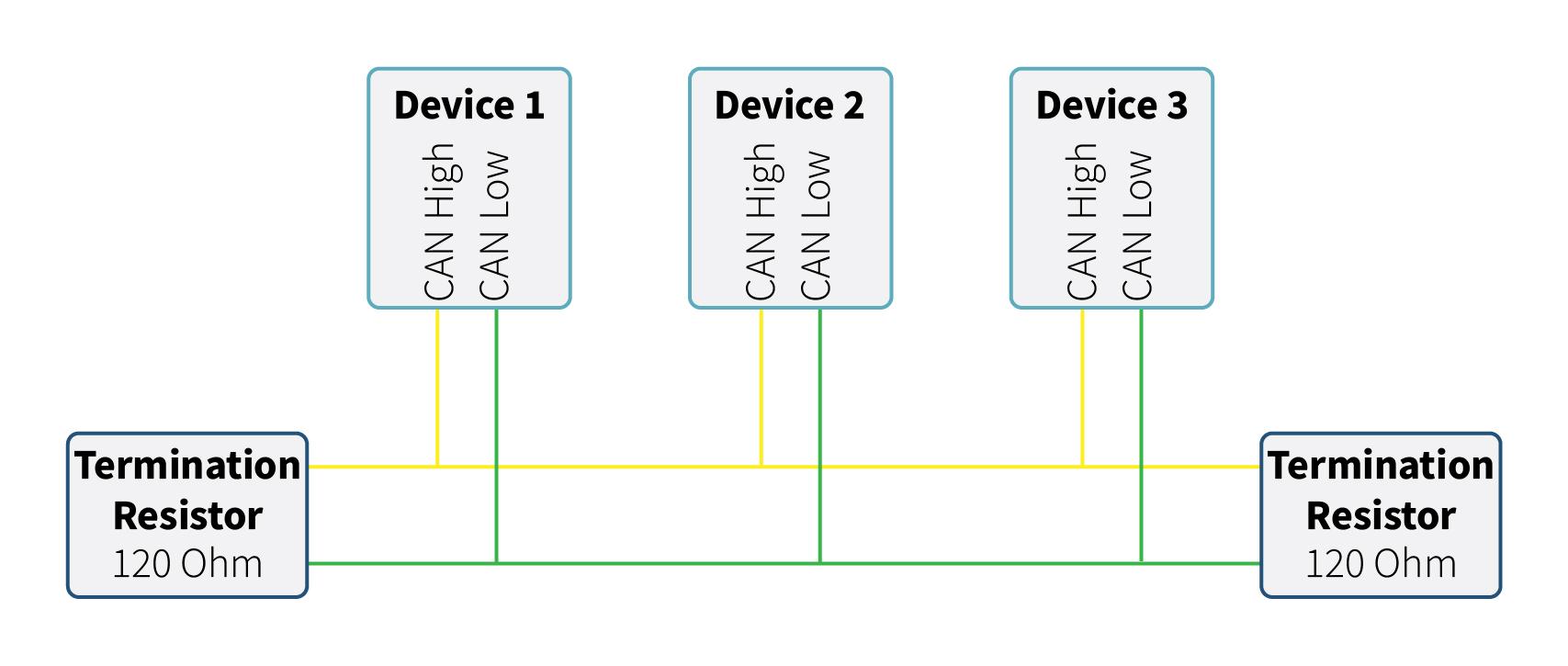

CAN Bus uses a linear bus topology with 120-ohm termination resistors at each end of the main bus line. These resistors are crucial—they absorb signal energy to prevent reflections that can cause communication errors.

Figure 1: Network Topoogy of a Simple CAN Bus

Figure 1: Network Topoogy of a Simple CAN Bus

Speed vs. Distance

The total bus length you can use depends on your baud rate:

1 Mbit/s → up to 40 meters

500 kbit/s → up to 100 meters

250 kbit/s → up to 250 meters

125 kbit/s → up to 500 meters

As a general rule: higher speed = shorter max bus length.

And remember: to avoid signal integrity issues, keep your stub lines short—ideally less than 30 cm.

Benefits and Limitations of CAN Bus

✅ Benefits

- Robust and fault-tolerant: CAN is built to survive in noisy environments.

- Flexible and scalable: Easy to add new nodes to existing networks.

- Low cost: No need for complex network infrastructure.

- Widely supported: Most microcontrollers and ECUs have built-in CAN controllers.

❌ Limitations

- Speed limitations: Standard CAN tops out at 1 Mbit/s.

- Bus topology constraints: Branches ("stubs") must be short—usually <30 cm.

- Length vs. speed trade-off: The faster your bus, the shorter it can be.

- Despite these limitations, CAN remains one of the most trusted protocols for mission-critical applications.

What’s Coming Next in the Series

In the next post, we’ll capture and inspect real CAN Bus data using an oscilloscope. We'll walk through what the signals look like and begin to decode how data is actually transmitted on the bus.

Stick around—we’re just getting started!